How you can reduce emulsion, the invisible grease thief

- Dec 1, 2015

Even if a commercial kitchen has an effective grease interceptor properly installed and maintained, fats, oils and grease (FOG) can still escape into the wastewater system.

While no grease removal system is 100 percent effective, a properly maintained, modern grease trap can still remove more than 99 percent of FOG found in kitchen effluent. One of the biggest obstacles to grease removal, though, is the invisible thief called emulsion.

Emulsion is a “fine dispersion of minute droplets of one liquid in another in which it is not soluble or miscible.” So what does that mean in plain English? And what can you do about it?

It happens every year during the holidays: Home cooks rev up their ovens and deep fryers and in go millions of turkeys in preparation for Thanksgiving day feasts.

It happens every year during the holidays: Home cooks rev up their ovens and deep fryers and in go millions of turkeys in preparation for Thanksgiving day feasts. Many local sewer ordinances require that food service establishments make their grease interceptors available for periodic inspection to ensure they’re working correctly, keeping fats, oil and grease (FOG) out of the wastewater system.

Many local sewer ordinances require that food service establishments make their grease interceptors available for periodic inspection to ensure they’re working correctly, keeping fats, oil and grease (FOG) out of the wastewater system. Across the country and around the world criminals are targeting a new kind of “liquid gold” — used cooking oil.

Across the country and around the world criminals are targeting a new kind of “liquid gold” — used cooking oil. The American Society of Mechanical Engineers (ASME) developed standards in the 1990s to govern passive hydromechanical grease interceptors. The standard was developed in collaboration with the Plumbing & Drainage Institute, and is referenced by the Uniform Plumbing Code, the International Plumbing Code and the National Standard Plumbing Code.

The American Society of Mechanical Engineers (ASME) developed standards in the 1990s to govern passive hydromechanical grease interceptors. The standard was developed in collaboration with the Plumbing & Drainage Institute, and is referenced by the Uniform Plumbing Code, the International Plumbing Code and the National Standard Plumbing Code. Food-service establishments aren’t the only businesses that have to keep oil and grease out of wastewater.

Food-service establishments aren’t the only businesses that have to keep oil and grease out of wastewater. Fats, oils and grease (FOG) in wastewater are one of the biggest challenges facing wastewater systems around the world. Grease, sometimes along with solids, can build up into a solid mass that can narrow or even block wastewater pipes. When that happens, sewers overflow, pipes break, and local authorities are forced to clean up the mess and make repairs.

Fats, oils and grease (FOG) in wastewater are one of the biggest challenges facing wastewater systems around the world. Grease, sometimes along with solids, can build up into a solid mass that can narrow or even block wastewater pipes. When that happens, sewers overflow, pipes break, and local authorities are forced to clean up the mess and make repairs. Though having a grease interceptor is required in virtually all commercial kitchens, there’s much more to controlling fats, oils and grease (FOG).

Though having a grease interceptor is required in virtually all commercial kitchens, there’s much more to controlling fats, oils and grease (FOG). A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.

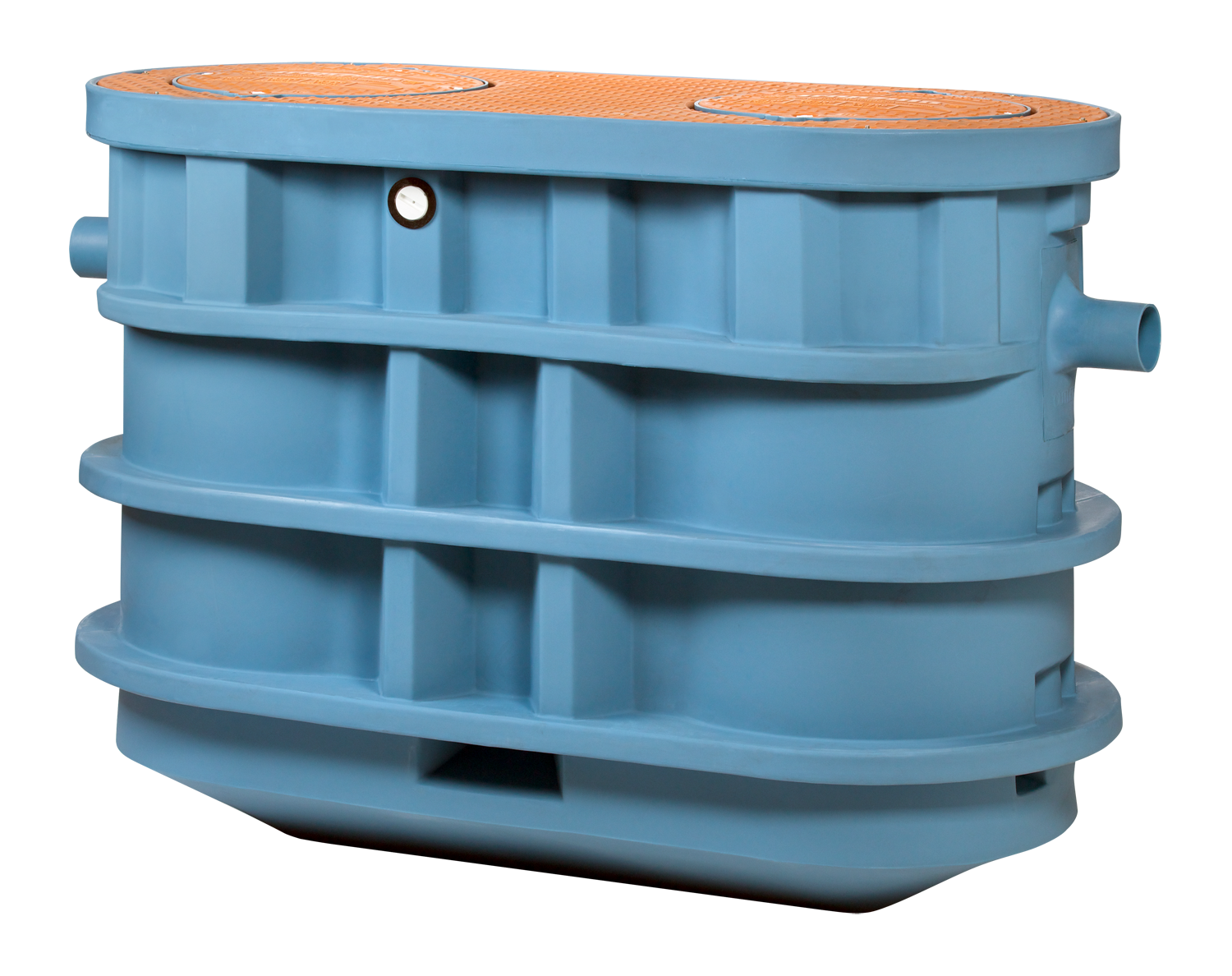

A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.  To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.