© 2020 Thermaco Inc. All Rights Reserved / Privacy Policy

© 2020 Thermaco Inc. All Rights Reserved / Privacy PolicyWHAT IS A GREASE TRAP?

Technically called a grease interceptor, a grease trap intercepts, captures, or traps grease as kitchen wastewater flows through before entering the sewer system. How?

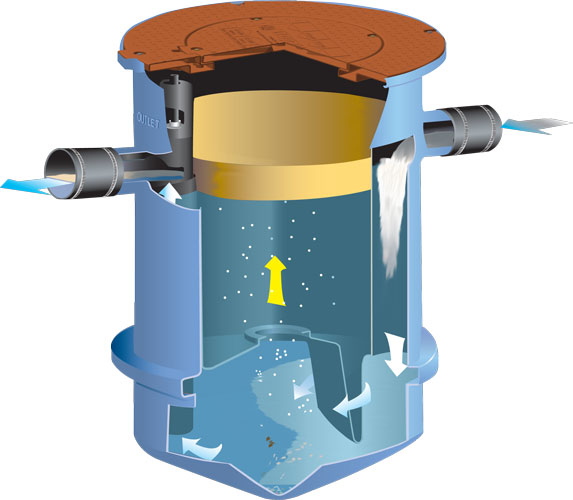

Because grease is 10-15% less dense than water, fats, oils and grease (FOG) float on top. When kitchen wastewater enters a grease interceptor, the grease rises to the top of the liquid level. This is possible through a system of baffles, plastic walls inside a grease interceptor tank to slow down and often control the flow of water. Captured grease fills the trap from the top down, while grease-free water exits through piping at the bottom of the trap into the following plumbing.

When you look into any grease trap, you should see a mat of grease. When this mat of grease gets deep enough, the trap must be emptied - usually by a pump truck.

See how a grease interceptor like Trapzilla works!

WHY DO I NEED A GREASE TRAP?

Sewer collection systems take waste water to a treatment plant, but there are some things they’re not designed to handle. One of those is grease.

Grease, especially from animal fats (think bacon grease), cools and solidifies at normal temperatures in pipes. That cooling, as well as other chemical reactions in sewer lines, causes blockages that lead to backups and sanitary sewer overflows (SSOs). Sewage overflows are a significant public health risk and require specialized equipment, time and manpower to clear.

Many cities require businesses that prepare food to install and maintain grease traps/grease interceptors. This requirement ensures grease doesn’t enter the sewer lines and reduces the risk of causing a SSO.

In some situations, a grease interceptor can save the food service establishment money. Any location with long internal plumbing, such as a mall, hospital, or restaurant inside a large building, runs the risk of blockages in the internal pipes. Those blockages could lead to backups, fines and even downtime while internal plumbing is repaired.

Grease traps need to be regularly cleaned out. If not, they will leak grease into the sewer system and cause blockages and sewage backups. This can result in fines, down-time, and bag publicity.

TYPES OF GREASE INTERCEPTORS

We have been in this industry for more than 35 years. Our interceptors, the Trapzilla and Big Dipper, are in tens of thousands of commercial kitchens on all seven continents. We’ve seen practically every type of grease trap and grease interceptor. To make sense of all the options, we can start with the three major types.

-

Small Passive Hydromechanical Grease Interceptors (HGI)

Hydromechanical grease interceptors (commonly called grease traps) often sit inside the kitchen underneath the sink or in the floor. They collect grease over time and need to be cleaned frequently, sometimes weekly. They may be less expensive up front, but in the long run they cost more due to the cleaning frequency required.

-

Gravity Grease Interceptors (GGI)

Gravity grease interceptors are often made of concrete, but can be built from steel, fiberglass or plastic. These interceptors often hold more than 500 gallons in liquid capacity. However, they can only hold a small percentage of that capacity in grease. These interceptors can be fairly large and require a large hole, sometimes the size of a small swimming pool, excavated to bury in the ground. They are not certified to meet any standards, so cities require them to be pumped out once they are 25% full of grease and solids.

Gravity grease interceptors are usually pumped every 90 days. Proper maintenance requires a pump truck and specialized equipment, resulting in hundreds of dollars in maintenance every year. GGI's can also degrade, fail, and require replacement as often as every 10 years. Since they are buried in the ground replacement is an expensive process requiring heavy equipment.

-

High Capacity Hydromechanical Grease Interceptors (HCHGI)

High Capacity HGIs, such as Trapzilla, have become more popular in recent years as restaurants open in more nontraditional sites. Often, these sites don't have space for a large concrete grease interceptor. HCHGIs take up less space and hold more grease as a percent of their liquid capacity — often between 70-85% of their liquid capacity or even higher as in the case of some Trapzilla models. These interceptors are 3rd party certified to meet efficiency standards. Most are made out of durable plastic or fiberglass, lasting much longer than concrete GGIs. They are usually lightweight and easy to install without heavy equipment. Most manufacturers test beyond the minimum standard to demonstrate the full capacity of the unit.

GREASE TRAP EFFICIENCY AND DESIGN

One factor that’s important when choosing a grease trap is efficiency. More efficient grease traps can hold more grease from your kitchen wastewater without taking up more space. That means a lower chance of blockages and overflows. Higher grease storage capacity keeps your interceptor functioning properly and makes it simpler and less expensive to install and maintain.

Grease traps have been around since the 1880s and many grease interceptors still use the same basic design as those early models. But design and engineering innovations in more recent years have allowed companies to develop new designs that are more efficient, longer lasting, and easier to use and maintain.

Early grease traps were made of concrete. Modern grease interceptors come in a variety of materials, including steel, fiberglass and plastic. The material used in grease interceptors affects their cost, weight, installation ease, ability to be moved, and durability.

Concrete can degrade, as can metal in some circumstances. Fiberglass tends to crack if moved. Modern plastics are lightweight and highly durable, and can make for long-lasting, highly efficient grease traps.

Compact, highly efficient grease interceptors, such as Trapzilla grease interceptors, are engineered so they never lose efficiency. They can hold upwards of 90 percent of their volume in grease before they must be cleaned out.

INSTALLATION CONSIDERATIONS

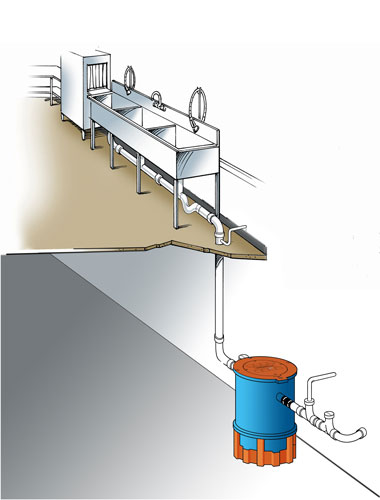

Another consideration with grease interceptor design is installation location. Do you have space outside to dig a large hole in the ground and bury the interceptor? Or does it make more sense to place the trap inside — in the kitchen or in a nearby space, such as a basement or other unused location?

Traditional gravity grease interceptors are installed outside. Usually a large hole is excavated, the concrete interceptor is lowered by crane, and connected to the kitchen pipes and sewer lines, then concrete is poured to hold it in place. This can be an expensive, time-consuming process.

When replacing an old grease interceptor, will the new one need to go in a different location, or can the existing location be reused? With large concrete interceptors it can be expensive and difficult to reuse the same location. Excavating and removing an old concrete interceptor may be too expensive to be practical.

Trapzilla can be installed in the location that makes the most sense for your commercial kitchen, whether it’s inside, outside, on the basement, or in the floor. They are often installed inside older interceptors, too, giving food service facility owners more choices.

Installation considerations are an important part of your decision process, so consider your site requirements and the ideal location before you choose a particular model.

HOW DO I START?

Now that you understand what a grease trap is, how they work, and the different types of grease interceptors. Are you ready to figure out which grease interceptor will work best for you? We’ve got an easy three-step process:

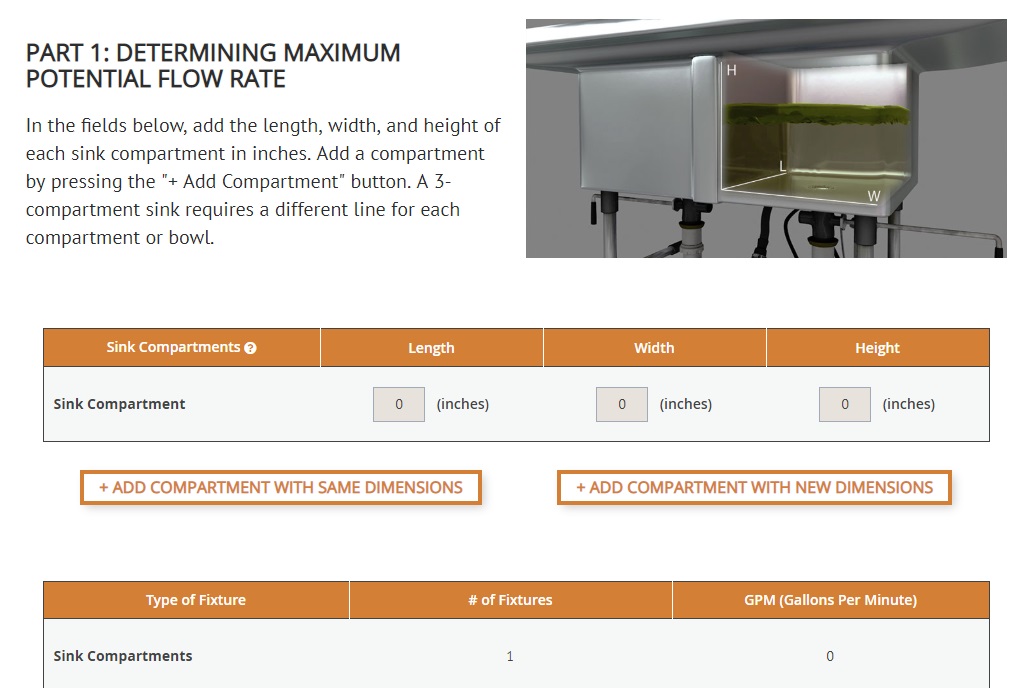

1. Use our easy online sizing calculator to determine the flow rate for your commercial kitchen and receive a free proposal. We can answer any questions you might have, especially with any regulatory issues and other considerations.

1. Use our easy online sizing calculator to determine the flow rate for your commercial kitchen and receive a free proposal. We can answer any questions you might have, especially with any regulatory issues and other considerations.

2. Schedule installation by a qualified local contractor. If you don’t already have a contractor selected, we can help you find one.

3. After your grease interceptor is installed, go back to focusing on what matters most to you — the customer experience — knowing your commercial kitchen is in compliance with local water and sewer regulations.

Not quite ready yet? We understand.

Maybe you want more information on how to select the best type of grease trap for your food service facility. Click here for a free guide that walks you through, step-by-step, the pros and cons for each type of grease interceptor and how to choose the one that will work best for you. Or maybe you have other questions about grease interceptors. Here are some additional resources to help.

· Replacing a grease trap? Here’s a few factors to consider

· How to calculate the total cost of ownership of a grease trap

· Grease interceptor design: a life-or- death decision

· Why concrete interceptors ought to be left in the history books

By understanding what a grease trap is and how different types of grease interceptors work, you’ve taken the first step in making the best possible decision for your commercial kitchen. Once it comes time to purchase and install an interceptor, you’ll be confident you’re making the right choice. You won’t have to worry about overflows, surprise expenses, or other grease interceptor traps. Instead, you’ll be focused on creating a great customer experience.